P1 Construction Navigates Unusual Requirements at Olathe Mental Wellness Campus

Since 2019, there has been a 60% increase in suicidal youth seeking care at the ChildrenŌĆÖs Mercy (Kansas City) ER.*

This sobering statistic is just one reason the new Olathe Mental Wellness Campus in Olathe, KS, is such a desperately needed resource.

The new facility broke ground in June, 2023, and is designed to reduce strain on the Kansas health system. The campus is a partnership of Camber Mental Health (part of KVC Health Systems) and ChildrenŌĆÖs Mercy, and will feature 72 inpatient beds: 24 for adults and 48 for children in crisis.

P1 Construction was selected as a design-build partner for the project and owned the engineerŌĆÖs contract for the ┴±┴½╩ėŲĄ and plumbing system.

The scope for the nearly $60M project included ┴±┴½╩ėŲĄ, plumbing, and controls. P1 performed all the installation for the ┴±┴½╩ėŲĄ equipment, ductwork, hydronic piping, and fixtures, while having CSC as a subcontractor for the controls.

P1 Construction is no stranger to healthcare, and has been working in this market for many years. Each healthcare facility comes with its own set of challenges, and the Olathe Mental Wellness Campus was no different.

P1 Cost Manager Nick Lawless was the project manager at the start of the project, before changing roles within the company.

Scan the QR code above to see a video about the project.

Scan the QR code above to see a video about the project.

P1 Project Manager Lauren Titzman (pictured, above) took over in Fall 2023.

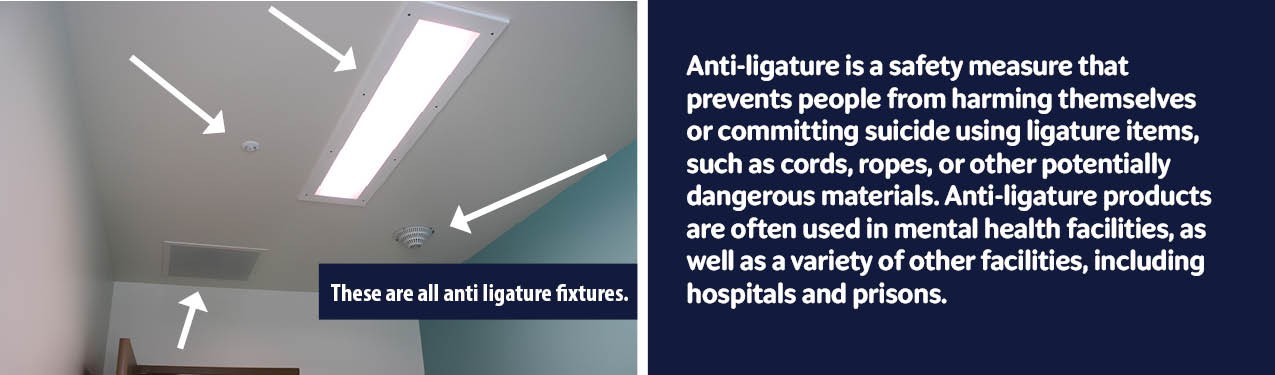

Lauren says one of the challenges on this job was the requirement to use anti-ligature fixtures.

Anti-ligature is a safety measure that prevents people from harming themselves or committing suicide using ligature items, such as cords, ropes, or other potentially dangerous materials. Anti-ligature products are often used in mental health facilities, as well as a variety of other facilities, including hospitals and prisons.

Lauren noted that these types of fixtures are expensive and can have a long lead time, but are essential in these facilities.

To help offset the longer lead time needed for anti-ligature products, P1 used a Gripple wire hanging system for the ┴±┴½╩ėŲĄ duct work and plumbing pipe.

Gripple is a system that uses cables to hold up the piping/ductwork, and is used by P1 for most all ┴±┴½╩ėŲĄ installations.

Pictured above: examples of Gripple duct and pipe suspension

Nick said Gripple hangers were recommended to him during the hand-off meeting.

ŌĆ£I looked into the process, and after seeing what it could do to save time on the piping side, we decided to run with it,ŌĆØ Nick said.

Plumbing pipe is typically hung with all thread rod (ATR) and various types of hangers - such as Unistrut trapeze hangers - to hold multiple pipes, clevis hangers, and auto grip hangers.

Nick noted that ATR requires more work than Gripple to install.

ŌĆ£ATR is measured, cut to length, then installed to the top of the building in various ways. It takes more time to assemble and adjust,ŌĆØ he said.

ŌĆ£Gripple is ordered in various lengths and strengths, depending on what youŌĆÖre hanging and the elevation. From there, you can use various options to attach, but you adjust it in the air to elevation and cut the excess length with a pair of snips.ŌĆØ

Between the plumbing and the piping combined, the project came in 38% under budget in labor and 27% under budget in material for hangers.

The keys to the facility were officially handed over to the owner in October, and the facility is expected to have its first patients in January, 2025.

Pictured, above: P1 Virtual Design and Construction (BIM) drawings next to the real thing in the mechanical room.

*Source:

┴±┴½╩ėŲĄ the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.