Berry Global/Berry Plastics

P1 has worked extensively at Berry Global’s 1.6 million sq. ft. thermoforming and injection-molding campus in Lawrence, KS, for more than 30 years.

P1 was not only able to adapt to Berry’s thermoform production style, we also has helped Berry increase its cup capacity to more than 7 million through the installation of VAVs, 30 supply fans, 27 make-up air units, four rooftop refrigeration units and three computer room air.

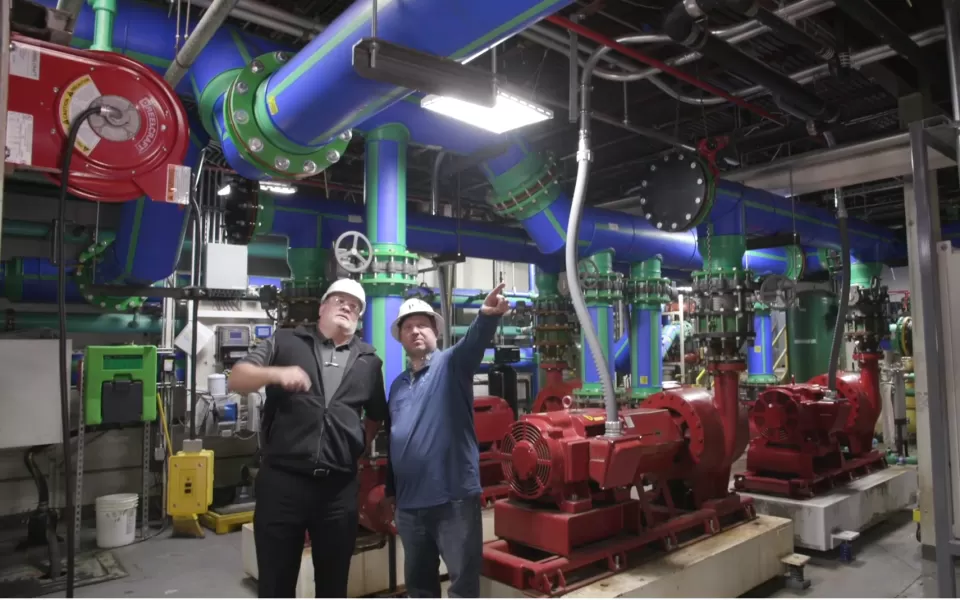

In addition, P1 recommended the use of Aquatherm pipe when the Lawrence plant needed to upgrade the chilled water piping for its injection molding process. The old steel piping was corroded and fouling the system’s water, causing loss of cycle time and productivity.

For the project, P1 installed more than 3,000 ft. of heat-fused Aquatherm pipe over one three-day weekend—a schedule that would have been impossible with steel pipe.

Services Provided

-

Commissioning

-

Design-Build

-

Detailing/Coordination

-

Electrical Construction

-

Piping Fabrication

-

Sheet Metal Fabrication

-

ÁñÁ«ÊÓƵ Construction

-

Plumbing Construction

-

Sheet Metal Construction

Quick Facts

-

9 2500 KVA Pad Mount Transformer

-

6 400A and 3 2500A electrical services

-

10+ miles of feeder conduit

-

43 miles of feeder conductors

-

34 Split System Heat Pumps

-

3,000 ft. of Aquatherm pipe

Project Details

Lawrence, KS

Ongoing

Food-grade pipe and plumbing

Need a team of professional specialty contractors to help with your next construction project? Get started by finding a P1 Construction location near you.

Still not sure if P1 Construction, LLC is the right fit? Feel free to check out more examples of our past work and hear from our statisfied customers.